天津市乐矿机械设备制造有限公司

企业简介

天津市乐矿机械设备制造有限公司是一家专业从事矿山机械设备和零部件研发、生产、销售和服务的企业, 主要产品有LCC 系列颚式破碎机、LCG 系列单缸液压圆锥破碎机、LCH 系列多缸液压圆锥破碎机和LCS 系列振动筛等。凭借专业的技术水平和诚信的经营方针,天津乐矿已经成为该领域知名的供应商和服务商,为矿山、建筑、钢厂、石料厂等客户提供优质的产品和服务。

天津乐矿拥有一支经验丰富、技术精湛、响应迅速的技术、销售和服务团队,为客户提供完整和及时的技术咨询、系统设计、建设安装、运行调试、保养维护和操作培训等服务。我们的团队始终致力于把降低客户的综合成本和给客户提供最大的综合收益作为我们的市场定位和追求目标。

Tianjin Luckcome Mechanical Equipment Co., Ltd is professional engaged in design, production, sales and service of mining equipments Manufacturing and components. Luckcome equipments include LCC series jaw crushers, LCG series single-cylinder cone crushers, LCH series multi-cylinders cone crushers and LCS series screens etc. Relying on the professional knowledge and honest operating principle, Luckcome has become a renamed supplier and service provider who can offer high quality products and services to mines, construction projects, steel plants and quarries. Our equipments can reduce cost for customers by replace the certain foreign brands equipments completely without any technological reform and engineering construction.

Luckcome has an excellent team which is experienced, skilled and responsive in both technique and service area. We draft individual plan for each customer in field of technical consulting, system programming, installation, running adjustment, maintenance and operational training. Luckcome devotes fully in utilizing the advanced technique, supreme quality and scientific concept into customers’ actual working condition requirements. We aim to reduce customers’ total cost and increase their final profit.

We’ve always believed in that Luckcome is valued by the final result we delivered to customers. This is the reason why we kept promise strictly and never accepted concession in products and service. Luckcome provides the most pertinent soluction and service plan to customers which bring them actual sustainable development in business.

联系方式:

矿业大会项目对接平台,王先生

电话:022-23295298

产品介绍

产品资料下载

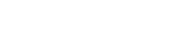

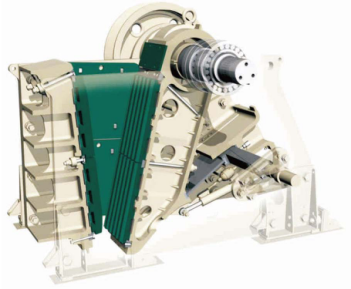

乐矿LCC系列颚式破碎机采用创新的模块化、无焊接框架结构,赋予了设备强大的抗疲劳性、可靠性和安装方式的多样性。该系列破碎机使用高质量的铸钢组件和一流的球型滚动轴承,充分保证了破碎作业的高产、高效和低成本。从坚硬的强磨蚀性岩石到各种再生物料,无论何种破碎需要,您都可以从LCC系列颚式破碎机中找到最佳解决方案。

Luckcome LCC series jaw crushers are based on a revolutionary modular, non-welded frame construction. This design brings the results of the highest possible fatigue strength, excellent reliability and numerous mounting possibilities. This, combined with high-quality cast steel components and premium spherical roller bearings, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton. Whatever your crushing needs-from hard and abrasive rock to various recycling materials-you’ll find the optimum solution with the LCC series jaw crushers.

设备特点与优势

Features & Benefits

世界级的工艺和材料

LCC系列颚式破碎机采用了独特的模块式、无焊接框架结构,两块热轧钢侧板通过紧固螺栓与精密加工的高质量铸钢机架牢固地栓接在一起;动颚总成采用高质量的铸钢件构成,通过两个大型铸造飞轮传动;锻造的重型偏心轴和四个同等规格的大型球型滚动轴承,使之具有超凡的可靠性;迷宫式密封保护轴承中的润滑油脂不被污染;整体的铸钢轴承箱能够保证与破碎机机架完全配合,并且还能避免对轴承造成过大的负荷。

World-Class Craftsmanship and Materials

A uniquely modular, non-welded frame construction is a state-of-the-art design with two hot-rolled steel side plates joined to high-quality cast steel frames through robust, precision machined bosses secured with bolts. The pitman is made of high-quality cast steel and is propelled by two massive cast flywheels. A very large eccentric shaft forging and four large spherical roller bearings that are all of the same size ensure the greatest reliability. The grease-lubricated bearings are kept free from contamination by means of well-proven labyrinth seals. The single piece cast steel frame bearing housings ensure a perfect fit to the crusher frame. They also prevent unnecessary loads to the frame bearings.

为降低破碎成本而特别设计

LCC系列颚式破碎机都装备有双楔块排料口调整系统,其坚固且调整快捷的优势在行业内已经得到证明,该系统在由于供电中断导致系统带负载停机而需要清腔时尤其有效;橡胶减震装置和限位块可以吸收震动峰值载荷,并允许破碎机垂直和纵向位移,从而有效地降低破碎机对基础的冲击;电机底座与破碎机机架一体安装,减少了破碎机安装空间和V形带的长度。

Designed for Your Crushing Costs Down

All LCC series jaw crushers are equipped with a proven, rugged and fast wedge setting adjustment system. The system is especially effective at clearing the crusher’s cavity should it stall under load due to interruptions in the supply of electric power. Rubber dampers and stoppers effectively decrease crushing loads to the foundation by absorbing peak shock loads and allowing the crusher to move vertically and longitudinally. An integral motor base is mounted on the mainframe of the crusher, thereby reducing the need for space and excessively long v-belts.

恰到好处的腔型设计

破碎腔是颚式破碎机的心脏和唯一的破碎工作区,因此LCC系列颚式破碎机的设计理念是“由内到外”。适当的给料口长宽比能够最大限度减少堵料的发生,并降低破碎机高度;采用大离心力和陡肘板倾斜角设计,使得在破碎腔底部有效冲程更大;大冲程、合适的转速、强劲的马力,保证了破碎机的高性能。乐矿开发了多种颚板,将颚板牙型和厚度不断优化并选用恰当的锰钢合金材料,既提高了产量又降低了客户的使用成本。

The Right Cavity Design

LCC series jaw crushers are literally designed “from the inside out” because the cavity is the heart and only purpose of the jaw crusher. The right feed opening width to depth ratio ensures minimum blockage and eliminates unnecessary height from the crusher. LCC series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge. The large stroke, combined with the right speed and high crusher power result in truly high crusher performance. Many types of jaws have been developed, the tooth profiles as well as the thickness of the jaws are optimized and combined with the right manganese steel alloys to maximize throughput and minimize operating costs.

易于实现自动化

如果选用液压调整排料口,LCC系列颚式破碎机可以完全集成在整个矿山的自动化系统中。破碎机的操控可以在破碎机旁的电气柜上或者操控室里一键完成。破碎机轴承的润滑也可以自动完成,轴承温度、破碎机转速和破碎腔料位都可以监测并完全集成在自动化系统中。

Easy to Automate

Due to their hydraulic setting adjustment, LCC series jaw crushers can be fully integrated into plant automation systems. The setting of the crusher can be changed from an electrical cabinet next to the crusher, or from the operator’s room, all at the touch of a button. The lubrication of the crusher’s bearings can also be automated. Bearing temperatures, crusher speed and cavity levels can all be measured and fully integrated into plant automation systems.

公司全资子公司山东天宝爆破有限公司是具有露天爆破、硐室爆破、地下爆破、拆除爆破以及水下爆破等一级爆破资质的专业爆破单位。可从事各类一级爆破设计施工、安全评估和监理,可以承担爆破新技术、新产品开发,爆破振动等公害监测、论证评估、矿山采掘工程总承包、大型土石方工程施工总承包等业务,是一家集科研、设计、施工、评估和监理于一体的综合性爆破公司。先后承担了胶南小口子“辽宁舰”航母基地、海阳核电入水口挡墙等军队及特殊环境控制爆破,青岛西海岸200万平方的采石爆破工程,济青高速、京沪高速、日东高速、长深高速等路垫、路堑开挖爆破,京沪铁路高边坡爆破和隧道工程等几十项道路交通工程爆破任务;主持济宁市主体8层、局部11层大楼、大型厂矿水囤、高危烟筒群、大型钢筋混凝土组合料仓定向拆除爆破工程;胶南董家口港水下炸礁及码头平场、山东山水水泥集团原料供应等项目的爆破施工任务;成为南山集团人工岛建设项目用现场混装炸药唯一供应商,该项目是山东省唯一获准实施的区域建设用海规划、首个规模化集中集约用海蓝色经济突破区、国内在建的最大海上人工岛群,并获得国家海洋局批复获准实施。

公司全资子公司山东天宝爆破有限公司是具有露天爆破、硐室爆破、地下爆破、拆除爆破以及水下爆破等一级爆破资质的专业爆破单位。可从事各类一级爆破设计施工、安全评估和监理,可以承担爆破新技术、新产品开发,爆破振动等公害监测、论证评估、矿山采掘工程总承包、大型土石方工程施工总承包等业务,是一家集科研、设计、施工、评估和监理于一体的综合性爆破公司。先后承担了胶南小口子“辽宁舰”航母基地、海阳核电入水口挡墙等军队及特殊环境控制爆破,青岛西海岸200万平方的采石爆破工程,济青高速、京沪高速、日东高速、长深高速等路垫、路堑开挖爆破,京沪铁路高边坡爆破和隧道工程等几十项道路交通工程爆破任务;主持济宁市主体8层、局部11层大楼、大型厂矿水囤、高危烟筒群、大型钢筋混凝土组合料仓定向拆除爆破工程;胶南董家口港水下炸礁及码头平场、山东山水水泥集团原料供应等项目的爆破施工任务;成为南山集团人工岛建设项目用现场混装炸药唯一供应商,该项目是山东省唯一获准实施的区域建设用海规划、首个规模化集中集约用海蓝色经济突破区、国内在建的最大海上人工岛群,并获得国家海洋局批复获准实施。

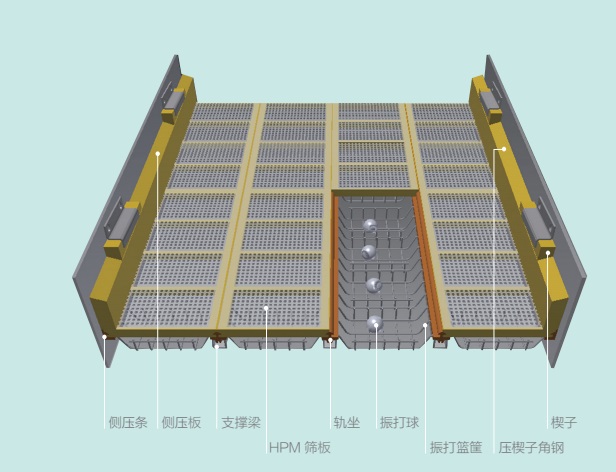

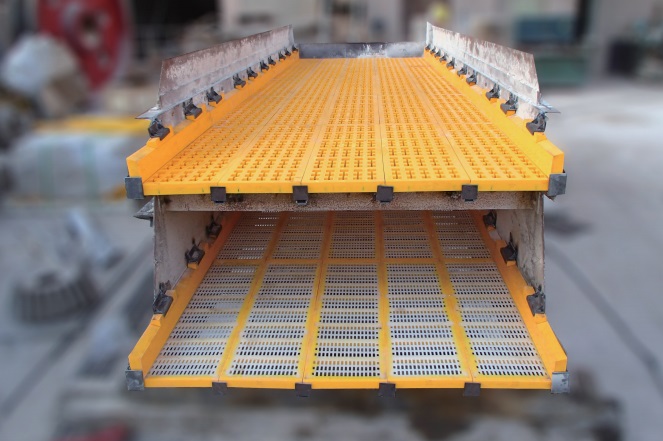

公司在实现高效筛分领域拥有前沿的技术理念、领先的生产工艺体系和先进的研发中心,并已取得多项专利技术。我们的产品和服务成功应用于煤炭洗选、钢铁冶金、选矿和矿粉制备、优质石材分选、泥水处理、资源再生和化工等领域。公司一直致力于提供高品质的产品和服务,提高筛分系统的运行效率,降低筛分系统的运行成本和能耗。

公司在实现高效筛分领域拥有前沿的技术理念、领先的生产工艺体系和先进的研发中心,并已取得多项专利技术。我们的产品和服务成功应用于煤炭洗选、钢铁冶金、选矿和矿粉制备、优质石材分选、泥水处理、资源再生和化工等领域。公司一直致力于提供高品质的产品和服务,提高筛分系统的运行效率,降低筛分系统的运行成本和能耗。